HUBERGROUP INDIA P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HUBERGROUP INDIA P.LTD

Aqueous Coatings

ACRYLAC

Water base over print varnish offer aesthetic look and protection to the print for various end use application, available as ACRYLAC brand in different varieties like gloss, satin, matt and high scuff.

The hubergroup’s ACRYLAC has been developed by our experts in our laboratories with combined knowledge provided by valuable customers & print buyers.

At the same time, carefully selected raw material and state-of-the-art production equipment ensure these quality products offer optimum performance.

Flexible Packaging

As the demand for colourful, flexible packaging continues to grow, so do the demands of the customers. We help our printers do this by supplying them not only with our continuously improved products, but also with a comprehensive service package that is right up with the state-of-the-art in printing techniques. And we offer you this technical know-how wherever and whenever you need it.

As a manufacturer of high quality printing inks, hubergroup is playing a leading role in creating solutions that meet the demands of discerning packaging printers. Special inks for food packaging, out-door exposure and low odour inks. Continuous research and development ensures that our products are always state-of-the-art. We offer a wide range of 'ink systems' to meet diverse printing conditions - water based, solvent based and inks based on different resin systems.

Lamination Adhesives

Laminating Adhesives for Flexible Packaging

The demands on packaging materials are getting more and more critical due to increasing awareness of product safety requirements worldwide. Flexible laminates are a major packaging material today and they must meet the expectations of converters and end-users. Adhesives are a key component in any laminate structure.

hubergroup range of lamination adhesives have been designed to fulfill these critical expectations. We have a range of adhesives for solvent based and solvent free applications. Our technical experts work closely with converters and brand owners to design products to the right specifications.

Metal Decoration

hubergroup India formulates and markets a wide product line of coatings and inks for metal printing application. Supported by continuous technological developments, it can meet emerging market demands with a total system of coatings and inks for virtually every can- and end-maker requirement. Its portfolio comprises of

● General Line Cans like Paint, Pesticides, Talcum powder, Aerosol and other products.

● Food Cans Processed food like vegetable, pure ghee, cheese, fruit pulp etc

● Closures like ROPP caps, twist off caps, crown caps

● Aluminium Collapsible Tubes

● Tin Printing Inks of various colours and white.

Also available are a range of FDA approved food lacquers. This range can be used for internal and external surfaces of most of the food cans. The cans are processable.

Along with coatings also available is a range of Metal Decorating Inks (Offset inks for Tin Printing), Aluminium collapsible tubes printing and UV inks for Tin Sheet printing. With the innovative flush technology for pigments, it is possible to make high loaded pigmented inks, with all the characters like gloss, sheen, and light fastness.

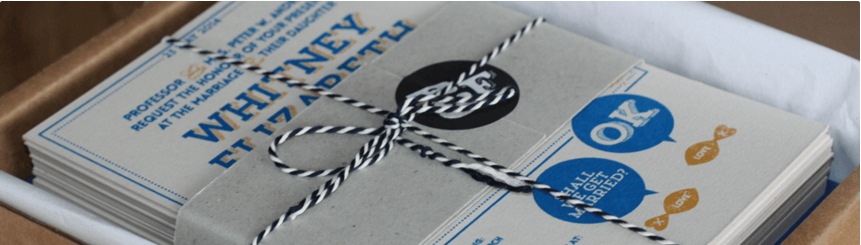

Offset Printing

Commercial printing has been subject to a lot of changes lately and success can only come with an ability to predict and adapt. Technological innovations and demanding customer expectations are the key drivers of these changes. This simply puts new demands on the pallet of consumables offered for print production – substrates, inks, coatings, fountain solution additives and more. hubergroup offers well optimized solutions to commercial printers all over the world. Be it Process Colours, Special Colours or Colour Matching Solutions – you can count on us as your most reliable partners

The products described here cover a lot, but we have more to offer. Should a question remain un-answered or if additional advice is necessary, please don't hesitate to contact us.

Press Chemicals

The big advantage printers have when the PRESS CHEMICALS & inks come from the same manufacturer. Since they have been developed together with the same high level technological & production quality they harmonise well together.

Our PRESS CHEMICALS are also compatible with latest plate chemistry on various press configuration.

A stable inks water balance is of crucial importance to achieve excellent print reproduction. hubergroup’s fount concentrates have been perfectly formulated by the technicians for optimum performance in varied print conditions.

Raw Materials For Ink Industry

hubergroup India manufactures a world class range of high quality raw materials for the ink industry.

We are among a handful of companies worldwide to offer the Alkali Blue pigments which are manufactured at our 'state-of- the-art' plant at Vapi, in Gujarat, India.

Alkali Blue, a unique pigment with a highly complex chemistry, is manufactured meeting the stringent quality standards and specific requirements of our valued customers.

We also manufacture an Adhesion Promoter Titanium chelate complex- API-002. This product does not contain any acetylacetone. The importance of this chelate is it is more resistant than titanium acetylacetone chelate to Phenolic antioxidants and is therefore much less likely to produce more colour in system where these antioxidants are present.

We offers versatile resins like Ketone Resins which are cost effective and soluble in a wide range of solvents.We also offer Polyvinyl Butyrals which offer excellent adhesion and film forming properties and are recommended for Flexo / Gravure inks and speciality coatings.

Also on offer are our Polyamide Resins.

Screen Printing

A GOOD & LASTING IMPRESSION ON ANY SUBSTRATE

Screen printing inks from hubergroup are formulated for consistent print results on various substrate under the most demanding environment.

hubergroup offers special range of screen inks for Graphics, Packaging, Electronics & Textile industries. The range comprises of conventional & UV curable system.

U.V Coating And Inks

NewV - The new generation of UV inks and coatings

Newly developed with the experience and passion of the hubergroup

Come and meet the new generation of UV inks and coatings. It's genuinely impressive: NewV from the hubergroup. A unique family of UV inks that offers a multitude of advantages: fresh, intensive colours, excellent flow properties, consistently high quality - you name it.... At the same time, NewV is suitable for use with a multitude of different substrates and printing processes, from offset, letterpress and flexo through to hybrid printing. At last, there's now a single product series on the market that lets you master almost all UV jobs: the hubergroup's NewV series.

NewV inks and coatings have been formulated keeping in mind the latest developments in UV technology. Working hand in hand with our clients, partners and technicians, we have listened to all their ideas and desires and incorporated them into this new ink generation. This means you can be certain to have a fully perfected and comprehensive UV ink system for your print production. NewV is manufactured in ultramodern production plants. By highly qualified personnel. And offers you maximum certainty in relation to choice, quality and availability

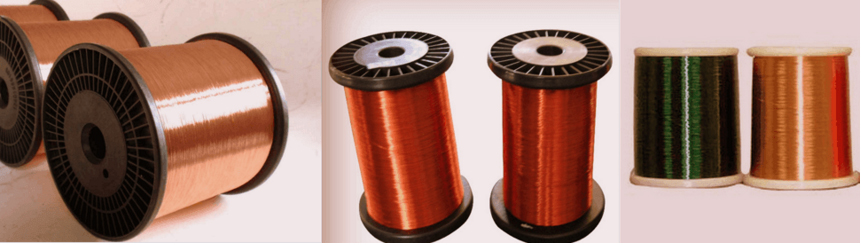

Wire Enamels

Hubergroup India manufactures Wire Enamels for insulation of Copper and Aluminum conductors. These enamels cover a broad range based on Modified Polyester, Polyurethane and Polyesterimide from class B (130 degree) to class H (180 degree) and Polyamide Imide (Top Coat) which are suitable for fine and thick wires, including strips.

Modified Polyester Based Wire Enamels

• MITSHINE R • MITSHINE RH • MITESTER FF • MITCUT F • MITESTER M/M • MITSUPER F 39

Polyurethane Based Wire Enamels

• MITSOLD S 30 • MITSOLD F 30

Polyesterimide Based Wire Enamels

• MITMID 35 • MICROMID 39

Polyamide Imide Based Wire Enamel

• MICROTHERM 35 DC

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.